Application

This machine is engineered for modern food industry applications, accommodating diverse production needs:

Breakfast Cereals: Extruded wheat flakes, nutrition bars, breakfast crisps

Snack Foods: Rice crackers with fillings, puffed shrimp sticks, fruit/vegetable chips

Plant Proteins: Textured vegetable protein (TVP), plant-based meat substrates

Infant Foods: Teething biscuits, fortified rice cereal, probiotic granules

Functional Innovations: Dietary fiber puffed products, microencapsulated nutrient carriers

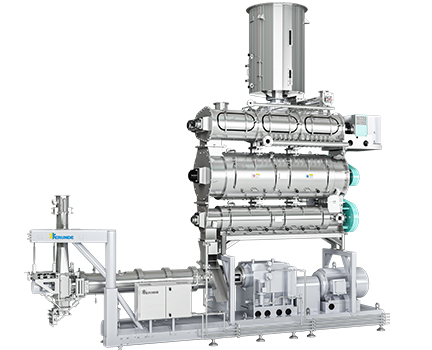

Features

◆ Intelligent Process Control

Modular screw design enables free combination of shearing/conveying/mixing elements for precise modulation of expansion ratio, texture, and density;

Multi-zone independent temperature control accommodates heat-sensitive ingredients while preserving bioactive integrity.

◆ Exceptional Material Versatility

High-torque drive system effortlessly processes high-viscosity, high-fat, and high-fiber formulations;

Self-cleaning screw configuration minimizes residue accumulation and supports frequent recipe changes.

◆ Energy-Efficient Production

Intelligent variable-frequency drive reduces energy consumption by 25% vs. conventional equipment;

◆ End-to-End Smart Monitoring

Integrated intelligent control system tracks pressure, temperature, and torque parameters in real time;

Cloud-based analytics predict maintenance needs to minimize downtime losses.

◆ Food-Grade Safety Assurance

Constructed with 316L stainless steel compliant with FDA/EC1935 standards.

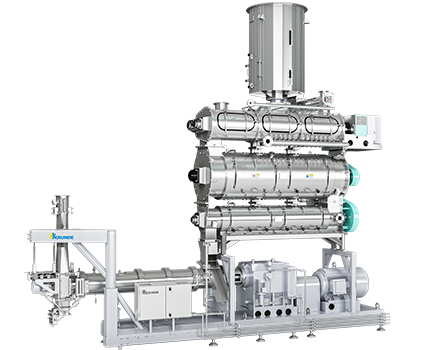

Model | Main power(kW) | Screw dia.(mm) | Capacity(t/h) |

| KDTE56x2 | 30 | 56 | 0.07-0.22 |

| KDTE75x2 | 55/75 | 75 | 0.3-0.6/1.0-1.5 |

| KDTE90x2 | 110/132 | 100 | 1.0-1.5/1.5-2.0 |

| KDTE120x2 | 160/200 | 132 | 1.5-3.0/2.0-4.0 |

| KDTE150x2 | 315/355 | 146 | 3.5-6.0/3.5-7.0 |

| KDTE180x2 | 710 | 176 | 6.0-12.0 |