Application

This equipment, with its efficient shearing force, precise particle size control, and low-temperature processing capabilities, is suitable for high-efficiency grinding of nutritionally fortified foods, functional ingredients, seasonings, snack foods, and health meal replacements. It meets stringent requirements in food processing for nutritional uniformity, bioactive compound preservation, and GMP-compliant clean production.

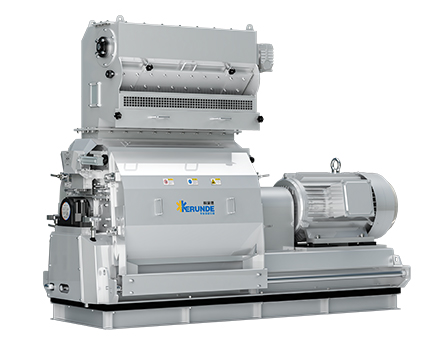

Features

◆ Featuring an optimized hammer matrix and food-grade stainless steel screen assembly, it achieves precise particle size distribution between 106-270μm. The innovative double U-shaped grinding structure increases fine powder yield by 20%, ensuring uniform dispersion of functional components in base ingredients.

◆ Stepless adjustment of screen-hammer clearance (0.3-2.5mm) accommodates diverse food materials including starches/sugars/fibers.

◆ Low-temperature grinding technology limits temperature rise to <6℃, effectively preserving thermo-sensitive components like vitamin C.

◆ Fully enclosed 316 stainless steel grinding chamber with ultra-low surface roughness prevents microbial retention. Combined with food-grade silicone seals delivering dynamic IP66-rated sealing, meeting HACCP contamination prevention standards.

◆ 0.4-0.6MPa food-grade compressed air pulse-screen system enhances self-cleaning efficiency by 50%. Quick-release access door with safety interlock enables rapid disassembly for sanitation.

| Model | Capacity(t/h) | Power(kW) |

| SFSP65x40w | 2.0-4.0 | 45/55/75 |

| SFSP65x60w | 2.5-5.0 | 45/55/75 |

| SFSP65x80w | 8.0-10.0 | 55/75/90/110 |

| SFSP65x100w | 7.0-13.0 | 110/132/160/200 |

| SFSP65x125w | 9.0-20.0 | 132/160/200 |

| SFSP65x150w | 13.0-20.0 | 220/250/280/315 |